Ceramic PCBs are viable for miniaturisation, says GSPK Circuits

In addition to its PCB and insulated metal substrate capabilities, GSPK Circuits is now supplying ceramic PCBs.

Recent advances in the market mean that ceramic PCBs have become a more viable option for PCB designers, explains GSPK Circuits. Requirements for miniaturisation, microelectronics and high-power LED packages accounts for the demand for substrates capable of withstanding high operating temperatures, whilst offering outstanding thermal performance.

Ceramics have thermal and mechanical advantages when used in electronics and electronic components. Advances in technology and manufacturing capabilities mean they are now replacing entire PCBs.

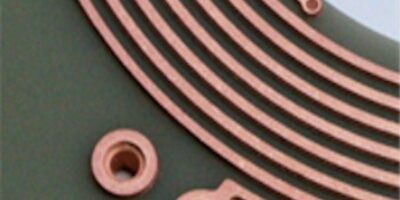

GSPK Circuits specialises in alumina oxide (Al2O3) and aluminium nitride (AIN) boards. Direct bond copper (DBC) and direct plated copper (DPC) technologies are used for the circuitry, depending on the requirements and/or applications.

Circuits can be printed using either copper (Cu) or silver (Ag).

If using a copper (Cu) track, solder resist, ident and surface finish options are much the same as conventional PCBs. For silver, a clear or glass solder mask is used. Gold plating can also be used in certain applications where the silver pads require protection.

The company’s service also includes technical assistance.