Yamaichi Electronics’ test sockets meet different package types

Test sockets, suitable for different package types are available from Yamaichi Electronics. The test socket series IC561, IC564 and NP584 have been developed to meet the miniaturisation and integration process of IC components. Major electronics manufacturers use different packages, said Yamaichi but there is often no standard solution available which means components manufacturers are forced to look for custom solutions in order to test their devices.

Yamaichi Electronics said its set of universal test sockets are as reliable as custom ones. The test sockets are versatile, making them usable for different package types having different dimensions, height and pitches. They offer a “semi-custom” solution at a standard price, said the company. The test sockets are applicable to all QFN (quad flat non-leaded), SON (small outline non-leaded), BGA (ball grid array), CSP (chip scale package) and LGA (land grid array) packages.

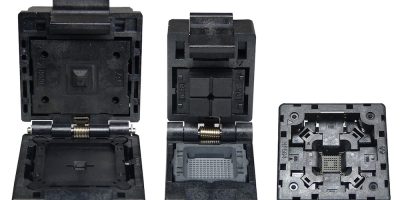

The clam shell type series IC561, its smaller “twin sister” IC564, and the open top version NP584, are made of different pre-processed parts designed to be easily assembled. Before the assembly these parts are modified using a milling process according to the specific package the socket will be housing. This gives the sockets a semi-custom feature.

The IC561 series is available for packages with dimensions ranging from 2.0 up to 18mm, with height ranging from 0.25 to 1.3mm, and with regular, irregular or even staggered pitch type of 0.25mm or higher. The IC561 has an outline of 38 x 35mm.

When smaller dimensions are needed, the IC564 series is designed for reduced dimensions of maximum 20 x 27.8mm. This series is available for packages ranging from 2.0 to 10mm2, with height ranging from 0.25 up to 1.3mm, with regular, irregular or even staggered pitch of 0.25mm or higher.

The lid is designed to push the package onto the contacts due to a spring-loaded system fitting different package heights. A custom-sized hole in the centre of the lid can convey an airflow directly onto the package.

For the IC561 series, it is also possible to mount onto or to integrate into the lid a cooling element simply by implementing few lid structure changes. This gives the customer the option of either active or passive thermal management control (TMC).

The NP584 series is designed for customers wanting an open top solution. This concept keeps the production costs near standard solution level, said Yamaichi, and gives the advantage of a semi-custom socket. The NP584 series has three form factors to allow a wider package range for open top solutions, from 2.0 x 2.0mm up to 20 x 20mm, according to the form factor.

The contact pin used for all the IC561, IC564 and NP584 series is a reliable probe pin, made of two single parts, one inserted into the other. It has all the benefits of compression mount technology (CMT) and is available in two versions depending on the contact type (pad or ball) of the package, advised Yamaichi. This type of pin ensures high performance both electrical and mechanical in a wide operating temperature range of -40 to +150 degrees C. Versions with low inductance features are also available.