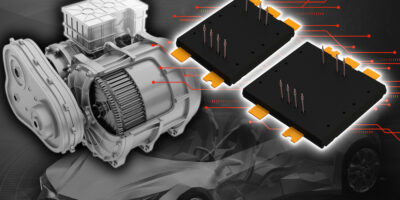

Rohm’s new TRCDRIVE pack reduces the size of xEV inverters

Rohm has developed four models as part of the TRCDRIVE pack series with 2-in-1 SiC moulded modules optimised for xEV traction inverters. TRCDRIVE pack supports up to 300kW and features high power density and a unique terminal configuration – help solving the key challenges of traction inverters in terms of miniaturisation, higher efficiency, and fewer person-hours.

As the electrification of cars rapidly advances towards achieving a decarbonised society, the development of electric powertrain systems that are more efficient, compact, and lightweight is currently progressing. However, for SiC power devices that are attracting attention as key components, achieving low loss in a small size has been a difficult challenge. Rohm solves these issues inside powertrains with its TRCDRIVE pack.

A trademark brand for Rohm SiC molded type modules developed specifically for traction inverter drive applications, TRCDRIVE pack reduces size by utilising a unique structure that maximises heat dissipation area. On top, ROHM’s 4th Generation SiC MOSFETs with low ON resistance are built in – resulting in an industry-leading power density 1.5 times higher than that of general SiC moulded modules while greatly contributing to the miniaturisation of inverters for xEVs.

The modules are also equipped with control signal terminals using press fit pins enabling easy connection by simply pushing the gate driver board from the top, reducing installation time considerably. In addition, low inductance (5.7nH) is achieved by maximising the current path and utilising a two-layer bus-bar structure for the main wiring, contributing to lower losses during switching.

Despite developing modules, Rohm has established a mass production system similar to discrete products, making it possible to increase production capacity by 30 times compared to conventional SiC case-type modules.