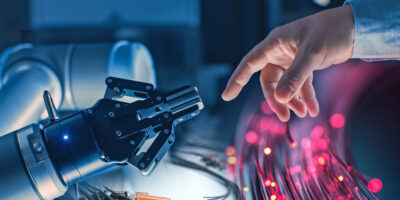

OMC deploys cobots to improve throughput of fibre optic production

OMC is investing to introduce innovative cobot technology onto its fibre optic production line in Cornwall. Following a research project with a local robotics lab and trials at its production facility, OMC is now deploying the first of several collaborative robots (cobots), designed to work safely alongside human operators in a shared workspace. The cobots will assist with labour-intensive repetitive and time-consuming tasks, where experienced human operators can often tire, increasing throughput and capacity up to 10x, while crucially maintaining quality and ensuring consistency.

OMC has been evaluating next-generation robotic automation technologies for some time—but has remained determined to balance potential efficiency gains against quality concerns and ensure the standards of performance, robustness and consistency demanded in long-life industrial applications are maintained. Having worked closely with its robotics partners to develop custom tooling and to train and calibrate the cobots, experienced operators are now working closely alongside the cobots to increase throughput and capacity while maintaining quality and ensuring consistency. Explains William Heath, Commercial Director, OMC: “Global electrification is driving increased demand for our fibre-optic datalinks—particularly for applications requiring isolation in high voltage, transportation and medical sectors—and this development allows us to respond with considerably enhanced throughput and efficiency. With each skilled operator supervising multiple cobots, productivity can be increased up to 10x, reducing time-consuming and repetitive manual tasks to improve their working environment.”