AI verifies EV batteries to reduce waste

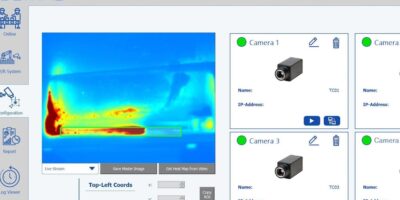

In-line testing and quality control developed by Comau, is claimed to optimise the construction and assembly of batteries. MI.RA/Thermography uses thermal imaging and artificial intelligence (AI) to perform non-invasive automated assessment and control of batteries’ welded joints. It has been added to Comau’s vision systems family of Machine Inspection Recognition Archetypes (MI.RA).

IR cameras and AI assess each welded joint before the final assembly. The company claims there is improved accuracy of aesthetic defect detection, often exceeding that of visual inspection.

Designed for industrial-scale battery manufacturing, MI.RA/Thermography uses a non-destructive testing methodology to protect cycle times without changing the existing manufacturing layout. Battery packs are composed of a large number of battery cells that are electrically connected by welded joints. High electrical resistance, due to poor joint quality, can create high energy loss and heat generation, thus increasing the joint temperature, provoking potential safety issues and reducing efficiency. By automatically assessing surface defects and the electrical resistance of each joint before final assembly, MI.RA/Thermography can save manufacturers time and costs, says Comau.

The system does not require an additional power source, as it is based on the in-line acquisition of thermal images that are immediately pre-processed, cropped and analysed via a knowledge-base. After receiving a trigger from the laser welding robot, the system records the cooling phase and performs features-based analysis to fully assess the joint quality.

Real-time results are collected and used for analysis and re-training.

“High-precision joining is vital in the assembly and integrity of a battery and the combined use of infrared vision and artificial intelligence enables Comau to non-invasively identify aesthetic, structural and electrical defects directly within the manufacturing process,” explains Giovanni Di Stefano, CTO – Electrification, at Comau. Comau delivers industrial automation products and systems. Its portfolio includes technology and systems for electric, hybrid and traditional vehicle manufacturing, industrial robots, collaborative and wearable robotics, autonomous logistics, dedicated machining centres and interconnected digital services and products able to transmit, elaborate and analyse machine and process data.

The company has over 45 years of experience and a strong presence within every major industrial country, helping manufacturers of all sizes in almost any industry experience higher quality, increased productivity, faster time-to-market and lower overall costs. The company’s offering also extends to project management and consultancy, as well as maintenance and training for a wide range of industrial segments.

Headquartered in Turin, Italy, Comau has an international network of seven innovation centres, five digital hubs and eight manufacturing plants.