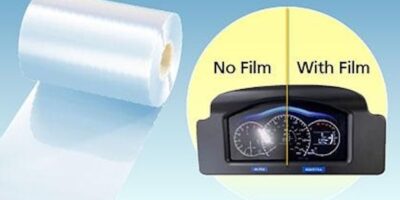

Anti-reflection, anti-glare film has automotive displays covered

Panasonic Industrial Solutions has commercialised an anti-glare type anti-reflection film for automotive displays. It has a low reflectance of 0.5 per cent and boasts “excellent weatherability” conforming to DIN standards.

MUAG8 (G200N) low reflection film is manufactured with a wet process. An industry trend is that automotive displays are increasing in size, with higher resolution, higher definition, odd form varieties, and improved operability. As a result, the displays are required to provide high visibility to allow drivers to instantly obtain information for ensuring safe and comfortable driving. This requires reducing reflection from the displays by laminating a film on screens to achieve such anti-reflection. This method addresses the need for larger screens and odd form varieties and also prevents screen glass from shattering upon impact. A wet process is used to produce anti-reflection films. Panasonic says it has achieved low reflection characteristics – with the reflectance reduced to 0.5 per cent or lower – by employing its resin design, hard coating material design and nano-coating technologies.

It also meets the DIN Standards related to deterioration under harsh use environments. Panasonic’s original design technology of optical materials achieves the new film with high infra red transmittance, which is effective when infra red sensors are installed as part of a driver monitoring system incorporated into the periphery of a display. This allows the film to transmit a greater amount of infra red rays. When the film can ensure the amount of infra red rays required for the sensors to detect incoming rays, the film can be attached to the surface of the display with the inside sensors fully covered. As a result, infra red ray transmittance exceeds 90 per cent.

Panasonic claims to be the first in the industry to achieve low reflection characteristics through a wet process with “excellent cost performance”.

Light incident to an anti-reflection layer reflects on both the front and the back surfaces of the layer. Optimising the refractive index and thickness of the layer can reverse the phase of the light reflected on the back surface, which can offset all light reflected on the front and the back surfaces to achieve a low reflectivity layer. Panasonic’s resin design and hard coating material design technologies laminate a combination of multiple high and low refractive-index layers and forms them into a film deposited onto a base film using its nano-coating technology. Light reflected from the formed film is reduced by the reflection offset, to produce the low reflectance (0.5 per cent or lower).

Samples are shipping now and mass production is scheduled to begin in April 2021.