Battery adhesive for hybrid cars bonds battery cells

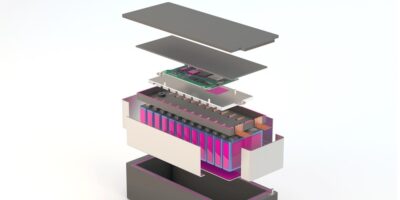

Thermally conductive battery adhesive from DELO is for use with hybrid vehicles. The DELO-DUOPOX TC8686 is a structural adhesive, designed for high-volume series production, and which is thermally conductive and flame-retardant.

The adhesive is suitable for low-voltage batteries in mild hybrid and conventional hybrid vehicles, as well as in e-bikes and e-scooters. It allows battery cells to be bonded into a battery’s housing while dissipating the heat generated during operation.

Instead of mechanically connecting the battery cells and then using gap fillers for heat dissipation, DELO-DUOPOX TC8686 simplifies production by combining connection of the thermal management system and structural bonding in one step.

The DELO-DUOPOX TC8686 is designed for temperatures ranging from -40 to +85 degrees C and offers strength on battery cells and typical housing materials. The tensile shear strength of the adhesive on aluminium is 18N/mm² and meets the strength requirements of the automotive industry at typical operating temperatures from 10 to 40 degrees C as well as at maximum service temperatures of 80 degrees C. Temperatures beyond this can result in irreversible damage to the battery electrolyte, notes DELO. The adhesive’s elongation at tear also helps to meet these requirements. A certain flexibility compensates for the different thermal expansion behaviours of cell and housing material during operation.

The adhesive has a thermal conductivity of 1.1 W/m*K. It also meets the requirements for flame retardancy according to UL 94 V-0.

DELO-DUOPOX TC8686 has been optimised for manufacturing processes. It offers a simple mixing ratio of 2:1 and has a processing time of approximately 30 minutes after mixing. This is long enough for prototypes and small series runs, while being fast enough for fully automated systems. After four hours, the adhesive reaches its initial strength. 90 per cent of its final strength can be achieved after 24 hours. Even with low heat input, this amount of time can be reduced significantly. Depending on the battery electrolyte used, a curing temperature of 60 degrees C can help to speed up assembly, says DELO.

The beige adhesive is easily detectable by cameras, for accurate application control. The filler for thermal conductivity is only slightly abrasive, contributing to the dispensing systems’ long lifespan, says DELO. The product is classified in transport category 1. It can be stored at room temperature.