GaN-based inverter enhances motor drive for e-mobility, drones and robots

Claiming to match premium motor drives’ performance, the EPCD9145 GaN-baed inverter is designed for e-bikes, e-motion, drones and robots, says Efficient Power Conversion (EPC).

The EPC9145 GaN-based inverter enhances the performance of the motor for range, precision, torque, says the company. Additionally, it eliminates the requirement for electrolytic capacitors, resulting in lower overall system cost and higher reliability. The small size allows the inverters to be integrated into the motor housing for the lowest EMI, highest density, and lowest weight.

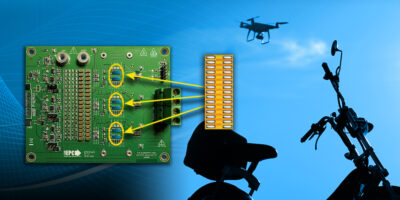

The EPC9145 demonstration board is a 1kW, three-phase brushless DC (BLDC) motor drive inverter which uses the EPC2206 eGaN FET.

The demonstration board features the 2.2 mOhm maximum RDS(on), 80V maximum device voltage EPC2206 eGaN FET. The board is tailored to e-bikes, e-motion, drones and robot motor applications. Its 48V bus voltage can deliver 15A RMS steady state at 50 degrees C temperature rise in natural air convection and can reach 20A RMS (28A peak) with a heatsink attached. The EPC9145 has been tested up to 100kHz, 60V input, and 50A peak.

The EPC9145 contains all the necessary critical function circuits to support a complete motor drive inverter, assures EPC. Board dimensions are only 130 x 100mm (including the connector). The EPC9145 also features the ST Microelectronics, STDriveG600, smart motor drive GaN half-bridge driver.

GaN FETs switch fast with zero reverse recovery, says EPC. This enables higher switching frequency in the 100kHz range to eliminate the need for electrolytic capacitors and to reduce the motor losses. Deadtime can also be reduced to approximately 20ns to allow higher torque per A. Overall, GaN devices improve inverter and motor system efficiency and reduce size and weight by integrating the inverter inside the motor.

The demonstration board highlights benefits of a GaN motor drive, such as lower distortion for lower acoustic noise, lower current ripple for reduced magnetic loss, lower torque ripple for improved precision, lower filtering for lower cost. The board’s low weight and size enables the driver to be incorporated into the motor housing. It also supports low inductance, higher power density motors, says EPC.

The company provides full demonstration kits, which include interface boards that connect this inverter board to the controller board development tool. Compatible controller interface and controller boards to the EPC9145 are EPC9147A for Microchip, EPC9147B for Texas Instruments, EPC9147C for ST Microelectronics, and EPC9147E as a generic interface board.

“Everyone wants a motor that is smaller, lighter, is less noisy, has more torque, more range, and greater precision,” said Alex Lidow, CEO of EPC. He says that eGaN devices, a cost-effective motor with a GaN inverter offer the same performance as an expensive motor with a silicon MOSFET-based inverter.

The EPC9145 demonstration board is available for immediate delivery from distributor, Digi-Key.