Inductive couplers revolutionise EV monitoring, says Premo

A series of inductive couplers, designed specifically for electric vehicle (EV) sniffing applications monitors the performance and safety of the high voltage systems. The MICU 300A-S/LF inductive couplers.

They are non-intrusive and offer an extended frequency range and minimal insertion loss providing combined narrow-band (30 to 600kHz) and broadband (2.0 to 40MHz).

The couplers have a sleek and compact design, engineered to be easy to install and use in rugged environments. Software equipment can be connected through different connectors (BNC standard / others upon request). Mechanical latch ease installation over cables up to 45mm diameter (current rate up to 300A, including shielded cables).

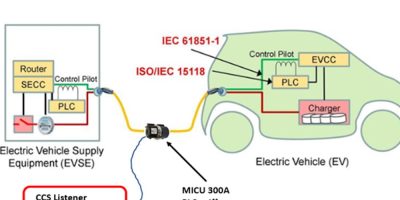

EVs present unique challenges when it comes to monitoring their high voltage systems, said Premo. Sniffing involves the use of inductive couplers to measure the current and voltage signals on high voltage cables, without the need for direct contact with the cables themselves. This non-intrusive method of monitoring is critical for ensuring the safe and efficient operation of EVs.

Sniffing applications allow for real time monitoring of the high voltage system, providing valuable insights into performance and safety. They can also help identify potential issues before they become serious problems, added the company. They can be used to gather data for research and development purposes, to improve the overall performance and efficiency of EVs.

The MICU 300A-S/LF series of inductive couplers use innovative core material and over-moulded insulation material to reach high voltage protection (up to 5kV) and EV charging quality standards (for example, HomePlug, V2G), making them suitable for CCS (combined charging system) communication protocol between a charging station and an EV. Waterproof versions, sealed to IP67, can be used outdoors.

The MICU 300A-S/LF series is available now from the manufacturer or its global network of distributors.

Premo is committed to SDG’s (United Nations’ Sustainable Development Goals) and designs, engineers, prototypes and test full reliability at its green carbon net positive Innovation Center. MICU products are engineered under sustainability standards that design for circular economy, considering 0km materials of natural origins, using green energy, and minimising the content of polymers from fossil fuels as well as recycled ferrites and copper.

Premo will be exhibiting at PCIM Europe 2023 (9 to 11 May 2023, in Nuremberg, Germany) Hall 6 – 232.