LPKF positions AMP laser system for volume IC package manufacturing

LPKF’s Active Mould Packaging (AMP) technology enables electrical circuits directly on the surface and inside the volume of the epoxy mould compound. This contributes to cost and space savings in advanced packaging manufacturing, and to a higher functional density of finished ICs, says LPKF.

The AMP technology is also designed to reduce power consumption, improve heat dissipation for power applications, enable additive 2L EMC-RDL formation and enables a suite of RF applications relevant for use in 5G.

More than ever, innovative solutions for mounting and connection technology are crucial factors in the semiconductor industry, says LPKF, and is made possible by AMP technology.

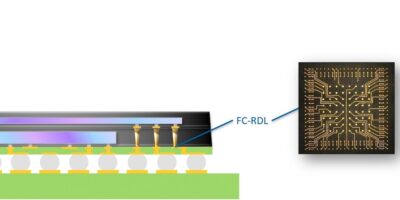

AMP simplifies IC and system in package (SiP) manufacture. For example, when using AMP, the epoxy moulding compound (EMC), which was previously used only to protect ICs or SiPs, is converted into an active carrier of electrical functionality. The simple, time-saving, and 2.5D packaging approach of AMP is based on three proven and standardised electronic production technologies: EMC encapsulation, laser processing using laser direct structuring (LDS), and selective metallisation of the laser-processed areas with copper.

A new class of epoxy moulding compounds (EMCs) has been developed for the laser direct structuring (LDS) process and is available in granulate and tablet form from a selection of suppliers. The material is also well-suited to the plating process, whereby laser direct structuring can reach a resolution range of 25 micron for each line width and space.

Active Mould Packaging enables direct, electrically conducting connections between active and passive components in an IC or SiP. This shortens electrical path lengths and thus Ohmic resistance and inductance.

Target applications of AMP are currently being developed for the 5G technology segment and beyond RF technologies. They can apply to mmWave antennae as antenna-in/on-package (AiP/AoP) modules that operate in ISM bands at e.g. 24GHz, 61GHz and 121GHz, vehicle radar modules that operate between 76 and 81GHz, 5G amplifiers, or even EMI shielding. Other applications are package-on-package (PoP), 2L interposers, multi-chip modules (MCMs), thermal management and SiP connections.