MLCCs deliver industry leading capacitance, claims Murata

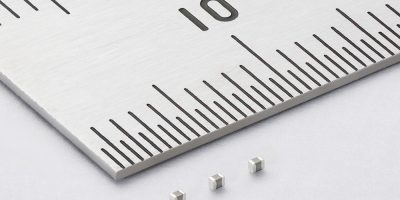

Passive technology manufacturer, Murata, offers the GRM series of multi-layer ceramic capacitors (MLCCs). The company says it is addressing the growing need for components that have elevated capacitance levels combined with miniaturised form factors and enhanced temperature performance. Offering capacitance values of 10 microF (and a ±20 per cent tolerance), the GRM series of MLCCs is supplied in a 0201 inch / 0603M package size.

The MLCCs are currently the smallest on the market to deliver such capacitance levels, said Murata. They represent a 65 per cent size reduction on the 0402 inch / 1005M products that would normally need to be specified. As a result, they enable the use of “substantially fewer components”, to save board space as well as bringing bill of materials costs benefits, said Murata.

The GRM series benefits from innovations, including the company’s proprietary thin layer forming technology, and a fully optimised high precision lamination process. The 4.0V DC-rated GRM035R60G106M MLCCs have a -55 to +85 degrees C temperature range and are in production today. The GRM035C80E106M with a rated voltage of 2.5VDC at -55 to +105 degrees C goes into mass production this September, and the GRM035R60J106M, with a rated voltage of 6.3V DC at -55 to +85 degrees C will be in production in 2024.

These MLCCs are suitable for incorporation into the decoupling and smoothing circuitry of smartphone handsets, portable equipment, wearables, domestic appliances, servers and IoT hardware.

“There are numerous market sectors where there is a definite need for capacitor components that have strong capacitance figures and also take up very little PCB footprint,” said Hidetoshi Nakagawa, general manager of ceramic capacitor marketing at Murata. “Furthermore, the miniaturisation of capacitors will contribute to reducing the environmental impact of the electronics industry and help enable long-term sustainability, with the quantities of materials involved being lowered and the amount of electricity consumed during their production also being curbed.”