Moulded backlight reduces set-up costs

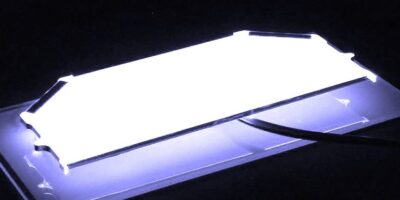

A moulded backlight series, announced by OMC, bridges the gap between profiled and moulded backlights.

Mouldshare backlights are manufactured using sliding-gate injection moulding techniques developed by the company which significantly reduce the usual set-up costs and minimum order quantities (MOQs) associated with producing a new backlight to a customer’s desired shape and size, claims the company.

The manufacturing process allows many different designs (from one or many customers) to be incorporated into a single injection mould tool. This reduces the set-up cost associated with an individual design and reduces minimum order quantities considerably, says OMC.

Set-up costs for standard moulded backlights are in the region of £5,000 to £10,000 depending on the design, explains OMC, whereas a typical MOQ would be around 20,000 units. OMC’s Mouldshare series reduces typical set-up costs to between £1,000 to £3,500, with MOQs as low as 500 pieces.

The series bridges the gap between the company’s Profiled backlight range which is manufactured using custom-engineered CNC profiling machines, have little or no set-up costs and MOQs as low as five pieces and the company’s standard moulded backlight range.

As with OMC’s standard injection-moulded backlights, designs can benefit from simulated multi-source (SMS) emitting elements and integral dispersion lenses to enhance uniformity and PCBs can be incorporated into the design allowing simple two-pin connection to the backlight and simplifying circuit design. Customers can also specify screw holes, mounting clips and other features to be moulded into their designs, reducing cost and enhancing versatility.

OMC’s commercial director, William Heath comments: “This new backlight series has proven very popular in our trials, as it is suitable for all standard backlight applications. A recent example of a design we manufactured using this new technology was a high brightness, high uniformity white backlight with an integrated PCB, 2 pin connection, about 35 x 45mm in size, used for an imaging application. Our customer was delighted that we were able to introduce this with a set-up non recurring engineering (NRE) costs of under £1,500 and MOQ of 500 pieces.”

OMC is one of the longest-established specialist manufacturers of optoelectronics in Europe; it is headquartered in Cornwall, UK. The facility is accredited to ISO 9001:2008, ISO 14001:2004 and OHSAS 18001:2007. The company is a pioneer in the development, manufacture and application of cutting-edge LED and fibre-optic technologies for a range of industries and companies worldwide, and places a major focus on research and development, engineering and innovation.

OMC has four key manufacturing divisions: fibre optics, LED backlights and optical mouldings, discrete optoelectronic components and semiconductor (LED) lighting.