Rohm develops a VCSELED infrared light source that combines features of VCSELs and LEDs

Rohm has established VCSELED, a new infrared light source technology that encapsulates a VCSEL (Vertical Cavity Surface Emitting Laser) element in a resin optical diffusion material for laser light. Rohm is currently developing this technology for commercialisation as a light source for improving vehicle Driver Monitoring Systems (DMS) and In-Cabin Monitoring Systems (IMS).

To further enhance automotive safety, driver monitoring systems are increasingly being installed in vehicles equipped with Advanced Driver Assistance Systems (ADAS) to detect drowsiness, sleepiness, and distracted driving. In Japan, the Ministry of Land, Infrastructure, Transport, and Tourism (MLIT) has created guidelines that define the design and functions of the system, and in the EU, there are plans to make installation mandatory in all new vehicles sold in Europe from July 2024 onwards. Automakers and suppliers are also developing in-vehicle monitoring systems to detect occupants other than the driver, and there is a growing awareness of the need for high-performance light sources that enable detection systems to function with greater precision.

In response, Rohm has developed VCSELED that achieves high-accuracy sensing. Minimal wavelength temperature variation combined with a wide emission beam angle make it ideal not only for in-vehicle monitoring systems, but also contribute to improving the accuracy and performance of inspection systems for robots and industrial equipment as well as spatial recognition and ranging systems.

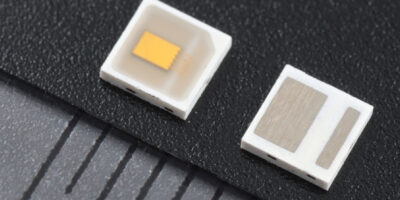

VCSELED extends the beam (irradiation) angle similar to LEDs by combining a high-performance VCSEL element and light diffusion material to enable sensing over a wider area with higher accuracy than VCSELs. What’s more, the light emitting element and light diffuser are integrated into a compact package, contributing to smaller, thinner applications.

The VCSEL element used in VCSELED features a narrow emission wavelength bandwidth of 4nm, approximately one-seventh that of LEDs. This characteristic improves resolution performance on the receiving side while eliminating the red glow often associated with LEDs. At the same time, a wavelength temperature variation of 0.072nm/°C – less than one-fourth that of LEDs (0.3nm/°C) – allows for high-accuracy sensing unaffected by temperature changes. Furthermore, the response time when emitting light is 2ns, approx. 7.5 times faster than LEDs, contributing to higher performance in ToF (Time of Flight) applications that use infrared light to measure distance.