Sensors automatically monitor mobile harbour equipment

Sensor Technology’s LoadSense, was originally used with helicopters carrying underslung loads in cargo nets and has now been adapted for use on ground-based materials handling equipment.

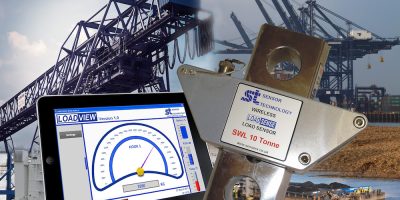

The technology involves a sensor being fitted to each crane or unloader. Once installed this does not interfere with handling operations at all, but constantly sends real time data via a wireless link to a computer, where it can be displayed, stored, totalled and analysed to provide performance information to the operators and billing information for the customers.

LoadSense is an intelligent load sensor that can easily be integrated with a mobile harbour crane. It is fully automatic so causes no disruption to normal operations. Special training is not required, said Sensor Technology.

The LoadSense sensor is based on proven strain gauge technology, and is calibrated as standard in the range of one to 50 tonnes, with other ranges available on request. The LoadSense constantly monitors the load and transmits this wirelessly, using the unrestricted 2.4GHz waveband, to a receiver for onwards transfer to the control computer. This enables accurate load data to be displayed, typically via a colour touchscreen computer, running Windows XP. The screen shows real time measurement of the load, while the computer records and analyses it.

LoadSense also enhances safety and prevents dockside handling equipment by constantly producing a digital signal to set up the control computer with an overload value that will trigger an alarm if it is breached. The computer will cut out lifting operations if the overload limit is breached, thus ensuring excessive loads are not raised off the ground.

LoadSense can also be used to keep count of the number of operational cycles performed, and signal when the equipment’s design life is being approached. An inspection can then be conducted to determine the likelihood of imminent failure in ageing equipment for remedial works to be undertaken.