Small pluggable power busbar coupler suits high density power applications

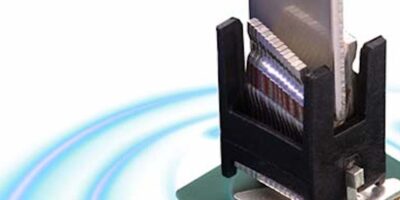

Streamlining assembly for high density power applications, the compact BusMate power busbar coupler has been released by Interplex.

The BusMate coupler is designed to maximise configuration options for product engineers to integrate busbars in power devices. It provides a compact, pluggable, and economical interface for connecting busbars to a variety of small PCBs, using either SMT or Press-Fit configurations. The coupler can support a range of designs, including blade-to-blade, moulded connectors and busbar-to-SMT (surface mount technology).

The BusMate power busbar coupler has a footprint of 8.4 x 6.0 x 9.9mm and is rated up to 80A or higher by using active or passive cooling designs. Its Floating Contact technology accommodates large assembly tolerances of +/- 0.8.

The coupler is constructed for high temperature operation, up to +150 degrees C and up to three re-mate cycles.

According to Joe Lynch, product portfolio director, “As smaller and more powerful product designs require compact, efficient, and reliable busbar interconnects for higher power densities, the BusMate power busbar coupler is giving designers new options.”

BusMate can be used in a diverse range of applications such as motors and pumps, hybrid vehicle power systems, electric power steering, charging systems, power mechatronics, brushless servo motor (brushless DC or BLDC) systems, traction-drive inverter busbar systems and other emerging power applications, speculated Interplex. Applications span a variety of industries including electric vehicles, e-mobility, charging stations, energy, transportation, industrial, ICT (information and communications technology) and medical and life sciences.

Interplex designs and manufactures customised connectors, high-precision and mechanical devices focused on trends around decarbonisation of transportation, future mobility, increased longevity and digitalisation.

Interplex operates in the fast-growing markets of electronification of cars, autonomous driving, medical and life sciences and the cloud, based on its combination of electromechanical (interconnect) and mechanical (high-precision) design skills.

The company has over 100 years of expertise, and said key OEMs and Tier 1s trust it to design, develop and manufacture best-fit solutions to reduce the total cost of ownership (TCO). The company has 33 locations across 13 countries and 12 R&D centres.