Smiths Interconnect describes Kepler as breakthrough contact technology

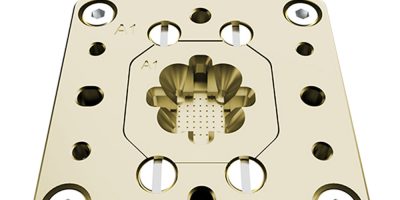

Two axis motion during a single actuation of the test socket is provided by the Kepler contact technology. It has been developed by Smiths Interconnect, and is claimed to the only contact technology for IC testing to provide this will boosts first pass yield. It is also claimed to enhance production reliability and extend maintenance intervals.

The technology can be used for testing high performance computing, wearables or automotive chips, confirmed Smiths Interconnect.

Presently, the semiconductor test industry uses the traditional vertical spring probes for BGA, LGA, QFN, and QFP packaging testing, or cantilever scrubbing contact design has been used in peripheral segments to remove surface oxides and contaminants. Both technologies, however, require maintenance and performance monitoring to ensure optimal results during testing cycles.

To address these issues, Smiths Interconnect developed Kepler contact technology that combines the scrub motion of a cantilever contact with the modular benefits of a spring probe. The design includes horizontal movement during the downward stroke of the device to break surface oxides, provide stable and reliable contact, and cause no damage to the PCB.

Brian Mitchell, vice president and general manager for Smiths Interconnect semiconductor business unit, said: “The continuing advances in semiconductor functionality, density, and chip-level integration are generating new challenges in testing and controlling the physical and electrical characteristics of the test contact interfaces. The piercing effect of spring probes on gold pads has been a challenge due to the build up of surface oxides. Additionally, the cantilever type has been associated with expensive PCB damage. Kepler overcomes the challenges posed by traditional vertical spring probes and cantilever scrubbing contact designs, providing a new level of performance and reliability.”

Smiths Interconnect provides high reliability connectivity products and serves segments of aerospace and defence, medical, semiconductor test and industrial markets. It designs and manufactures technically differentiated electronic components, microwave, optical and radio frequency products and sub-systems that connect, protect and control critical applications.

Smiths Interconnect is part of Smiths Group, which has been established for over 170 years and serves customers across four major global markets – energy, general industry, security, and defence and aerospace.