Diodes are packaged for sterile environments

Two short wavelength ultraviolet emitting diodes are in ceramic / quartz-based packages and available from Vishay Intertechnology. The UVC (short wavelength ultraviolet) emitting diodes offer higher radiant power at a lower cost than previous generations, said the company.

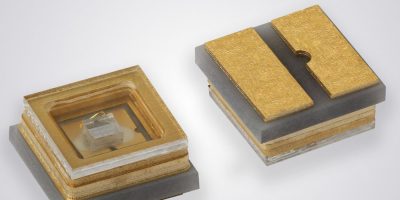

The Vishay Semiconductors VLMU35CR40-275-120 and VLMU35CR41-275-120y are supplied in a ceramic / quartz-based package for sterilisation in medical, industrial, and consumer applications. Compared to previous generation, they deliver higher radiant power at a lower cost while offering higher disinfection efficiency and a longer service life, said Vishay.

Typical radiant power is 37mW at 250mA, which in terms of mW/$ performance is 30 per cent higher than lower power emitter diodes and 12 times better than previous generation devices, according to the company. The VLMU35CR41-275-120 provides a minimum radiant power of 30mW at 250mA, which is the same as the closest competing device at 350mA.

The emitter diodes offer a wavelength range of 265 to 280nm, with a typical wavelength of 274nm. Not only is this suitable for direct disinfection of surfaces, air, and static water, but compared to 280nm diodes, the VLMU35CR40-275-120 and VLMU35CR41-275-120 are claimed to deliver 20 per cent higher sterilisation efficiency. The diodes are supplied in a compact, thermally optimised, surface mount 3.45 x 3.45 x 1.7mm package with a ceramic substrate and quartz window. Service life is 27,000 hours at 250mA and 25 degrees C.

The devices feature DC forward current up to 300mA, forward voltage down to 5.2V, and an emission angle of ± 60 degrees. The VLMU35CR40-275-120 and VLMU35CR41-275-120 are RoHS-compliant and halogen-free. They are compatible with reflow soldering processes and feature a moisture sensitivity level (MSL) of 3 in accordance with J-STD-020.

The VLMU35CR40-275-120 and VLMU35CR41-275-120 are built on AlGaN technology and designed to replace low pressure UVC mercury tubes, particularly in compact designs. Typical end products include medical instruments, sterilisation devices for ear buds, toothbrushes, water bottles, refrigerators, air purifiers, door handles, coffee machines, ATMs, toilet seats and vacuum cleaners.

Samples and production quantities are available now, with lead times of eight to 16 weeks.