Nomogram simplifies parameter calculations in DCM flyback designs

Claimed to maximise overall efficiency, Pulisiv has developed a nomogram to help design engineers rapidly determine critical transformer parameters in DCM flyback designs.

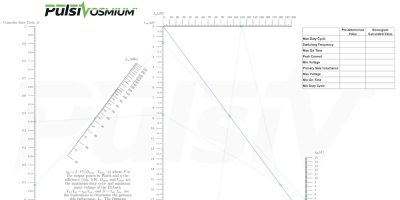

The tool can replace more complex equation-based methods, providing a fast and accurate visual process for identifying primary side inductance and minimum duty cycle, said Pulsiv.

The field of nomography was invented in 1884 by French engineer and mathematician, Philbert Maurice d’Ocagne to provide engineers with a precise and practical method for calculating complicated formulas using a parallel co-ordinate system. Results from a nomogram are obtained quickly and reliably by simply drawing one or more lines, without needing to solve algebraic equations.

Combining DCM flyback designs with a Pulsiv OSMIUM AC/DC front end maximises overall conversion efficiency, reduces energy waste, and lowers cost across a range of power electronics applications including USB-C devices, LED drivers, and battery chargers.

The Pulsiv nomogram consists of four steps. The first is the switching frequency and maximum duty cycle when users note the switching frequency and maximum duty cycle of a chosen flyback controller.

The second step is to select the required peak current (based on the output power) and minimum flyback operating voltage.

The next step addresses the primary side inductance and minimum duty cycle. Users need to draw straight lines across the nomogram to identify suitable values for primary side inductance (for the DCM flyback) and minimum duty cycle (based on the maximum flyback operating voltage).

The final step is to check the flyback controller datasheet. This is to ensure that the minimum duty cycle, calculated from Step 3, can be achieved. Some controllers change the switching frequency based on the operating voltage of the flyback, and this must be considered when using the nomogram to determine the minimum duty cycle.

DCM flybacks are a popular choice in low to medium power designs where isolation is required. They are often paired with a boost PFC front-end stage with significant switching losses under low load conditions and poor average efficiency.

Pulsiv OSMIUM technology uses a patented switching technique by applying intelligence to an active valley fill approach for converting AC/DC. The company said this method offers several advantages, including a front-end efficiency of 97.5 per cent, (99.5 per cent peak) and 90 per cent at 2W; a totally flat efficiency profile across the entire load range; input voltage derating and inrush current are eliminated and it extends the range of single-switch flybacks to 180W.