Relative pressure sensor IC measures pressure in automotive evaporation systems

Relative pressure as low as 50mbar can be measured with the automotive-qualified MLX90821 sensor.

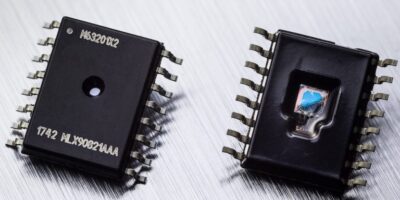

Melexis has designed the relative pressure sensor IC using MEMS technology closely integrated with an analogue signal chain and digital signal processing (DSP). The MLX90821 is a system-in-package (SiP) IC to measure fuel vapour pressure from 50 to 700mbar. Melexis confirms that the MLX90821 is suitable for evaporation systems designed for internal combustion engine or hybrid vehicles.

Implementing fuel pressure vapour detection is increasingly important, as more regions introduce strict legislation which prohibits the venting of fuel vapour to the atmosphere. As vapour builds up inside fuel tanks and crank cases, the evaporation systems are designed to capture, store and responsibly dispose of the vapour, preventing it from escaping into the air. Pressure sensors that can operate at very low pressures are able to detect even the smallest leaks that can potentially appear at any point in the evaporation system.

The MLX90821 has the range, reliability, stability and accuracy to cover evaporation systems for both internal combustion engines (ICE) and hybrid engines, enabling Tier 1 and module manufacturers to standardise on a single design for both types of engine, using a sensor IC that is factory-calibrated but can also be customised for each application. It is certified to operate between -40 and +150 degrees C.

Fuel vapour pressure measurement is even more complex in hybrid vehicles, adds the company. Both analogue and Single Edge Nibble Transmission (SENT) protocol outputs are provided. The DSP allows designers to make full use of the SENT interface’s fast channel and slow channel, add diagnostic messaging and apply custom calibration. Automotive diagnostic features include clamping levels, broken track diagnostics and multiple internal fault diagnostics.

The SiP uses a MEMS sensor manufactured through back-side etching. This allows the sensing element to be exposed to the vapour or other media and protects against contaminants. The sensor protects against EMC and offers EMI.

Each sensor IC is calibrated during the final steps of manufacture, with the pressure transfer curve and clamping levels stored in the internal EEPROM. The measurement is provided through the ratiometric analogue output or as a SENT output, which may also contain temperature measurements. An optional NTC temperature compensation feature makes use of an external NTC, which may be required when the application also needs to record an accurate temperature measurement of the media being monitored. Further configuration is possible using software tools provided and supported by Melexis.