Rugged module brings AI to harsh but safety-critical environments

Harsh industrial environments, ranging from factories and farms to refineries and construction sites need inspection and maintenance as part of everyday operations but conditions mean these may not be suitable for human beings to conduct.

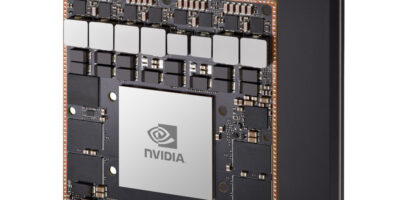

Robotics and automation are increasingly used in manufacturing, agriculture, construction, energy, government and other industries, but without AI and deep learning. Nvidia has developed the Jetson AGX Xavier Industrial module, built for intelligent video analytics, optical inspection, robotics, computer vision, autonomy and AI in the toughest environments. The module can be used to deploy AI at the edge in harsh environments where safety and reliability is a critical priority.

This industrial module extends the capabilities of the Jetson AGX Xavier system on module and allows developers to build advanced, AI-enabled ruggedised systems.

The compact, power-efficient design delivers up to 30 trillion operations per second (TOPS) of AI performance. It is built with components tested to demanding industrial standards and including new functional safety capabilities, and to withstand severe shock and vibration and extreme temperature ranges. It is pin-, software- and form-factor compatible with the existing Jetson AGX Xavier module.

Jetson AGX Xavier Industrial combines the supercomputing capabilities of the Jetson AGX Xavier system-on-module with new reliability, availability and serviceability features required to deploy AI in tough environments. These include error correction codes, single error correction, double error detection and parity protection to deliver internal RAM resilience, address and data bus error detection and correction and IP resiliency in industrial applications.

The module comes with functional safety capabilities supervised by the Safety Cluster Engine (SCE), making it suitable for safety-certified industrial-grade products. In addition, it has the same key accelerators and high-speed I/Os included with Jetson AGX Xavier.

Jetson AGX Xavier Industrial features a 512-core Nvidia Volta GPU with 64 Tensor cores, two Nvidia deep learning accelerators, two vision accelerators, an eight-core Nvidia Carmel Arm CPU, an encoder and decoder. The SCE contains dual Arm Cortex-R5 processors that can be used for integrated fault-detection mechanisms, lock-step subsystems and enables built-in-system test. The Cortex-R5, which is in an always-on domain, can be used for safety and error correction functions.

It also includes hardware-verified secure boot, hardware-accelerated cryptography, support for encrypted storage, memory, and other security features to protect customer software.

Powered by the Nvidia CUDA-X accelerated computing stack and JetPack software development kit (SDK), Jetson AGX Xavier Industrial is a fully software-defined platform enabling cloud-native capabilities. Nvidia’s CUDA-X acceleration, free production-ready pre-trained models on NGC and Nvidia Transfer Learning Toolkit give developers the fastest path to build and deploy deep learning and AI training and inference systems.

With the Jetson AGX Xavier Industrial and JetPack, customers can maintain and update ruggedised and safety critical systems in the field using cloud-native technologies for orchestration and management.

The Jetson AGX Xavier Industrial can be used in industrial, aerospace, defence, construction, agriculture, logistics, inventory management, delivery, inspection and healthcare applications.

For example, in the oil and gas industry, it streamlines anomaly and failure predictions at the edge by providing real-time insights based on monitoring or inspection of pipelines, valves, equipment and maintenance work. The module is reliable for use in safety, predictive maintenance and compliance and where equipment remains always-on in changing environmental conditions.

In automobile manufacturing facilities, a factory producing more than 1,000 vehicles a day needs to inspect over six million welding points on-the-fly. Using its AI and computer vision, the Jetson AGX Xavier Industrial can analyse process and qualify data directly from weld guns, which reduces inspection time and improves quality prediction, says Nvidia.

Another example is to detect anomalies in die-casting processes using AI. Early prediction of product quality avoids further process costs and decreases defect rates by up to 40 per cent, reports Nvidia.

Similarly, construction sites employ heavy equipment that must operate reliably in various climates. Other examples are farm tractors which carry fertilisers and herbicide sprayers, and harvest thousands of acres of crops on various terrains. There are also unmanned aerial vehicles (UAVs) and drones which can experience extreme shock and vibration while flying in harsh environments. Other examples of applications are point-of-care ultrasounds and patient monitors require consistent operation over long lifetimes.