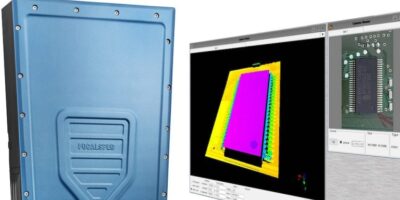

Sensor and software combine to inspect surface mount devices

Images taken with the FocalSpec sensor are used by EVT’s EyeVision software to inspect the pins on surface mount component parts. This is necessary, says EVT, because, despite being checked several times during the production, there still can be some errors on the parts.

Pins can be bent from the handling or the assembly. This means that the pin has no contact with the soldering paste. Yet, because the pin is bent upwards, the 2D camera may not detect the error.

The surface mount components have reflective parts which can hinder the detection of imperfections. The reflective surface of the metal reed on surface mount devices means it is difficult to determine their height. Also, the tin-lead solder is reflective due to its silver shine.

The FocalSpec captures a perfect image of the pin height, says EVT. Therefore it can be inspected on the PCB to check if all pins have the same height, which means that they have electrical contact. Soldering paste is also clearly visible in the scan and can also be inspected using FocalSpec and EyeVision software.

The FocalSpec sensor supports the ChipControl command set of the EyeVision software to enhance the image with the right image capture element. As a result, already-assembled surface mount component parts can be inspected, assure EVT.