Terminal blocks improve assembly efficiency

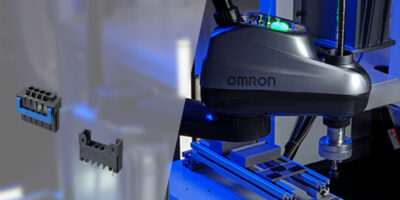

Push-in terminal block PCB connectors “significantly improve” the efficiency of connector insertion and removal and cable wiring during assembly, according to Omron Electronic Components Europe. The XW4M and XW4N connectors can be used in factory automation applications, such as robot controllers, AC servo drivers and CNC machines.

The XW4M and XW4N reduce the space required in designs, by having a low board profile. They achieve a very low insertion and extraction force while retaining high quality contact reliability. They are available as a double-row or single-row socket or plug.

In addition to benefits of size, Iker Saenz, product marketing manager, Omron said the connectors will also enhance the efficiency of inspection, assembly and maintenance.

The XW4M and XW4N connectors are designed for simplicity of assembly, which should eliminate human error. Wiring efficiency is improved with a hands-free mechanism that keeps a screwdriver inserted, saving time and reducing risk of errors, said the company. The clear embossed pin numbering on the packaging is also designed for safe, simple assembly. A safe locking mechanism decreases the possibility of accidental release of wires.

Omron Electronic Components Europe supplies electromechanical PCB relays, as well as components such as micro switches, MOSFET relays, DIP switches, photo-microsensors and connectors. Omron has a strong portfolio of innovative technologies including MEMS-based pressure, flow and thermal measurement sensors, human face and gesture recognition modules, vibration and tilt sensors.

Omron Electronic Components Europe supports its customers in western and eastern Europe, Russia and the commonwealth of independent states (CIS) through eight regional offices, a network of local offices and partnerships with specialist, local, regional and global distributors.