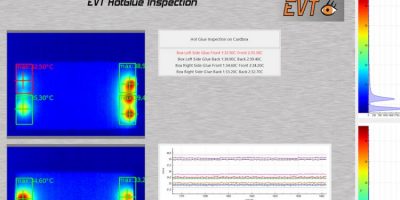

Thermal imaging inspection monitors adhesive points

Equipped with digitial interfaces, the EyeVision HotGlue system has allows for autonomous operation in a plant as it inspects the adhesive points between cardboard surfaces of boxes. Autonomous operation can be carried out via a Profinet interface in the EyeVision software to integrate the systems into a programmable logic controller (PLC).

The HotGlue Inspector inspects, if the adhesive points between cardboard surfaces of boxes, are present and hot enough to glue the cardboard box together. It can monitor up to 60 boxes or bottles per second (or 3,600 boxes per minute).

The cameras can be arranged so that the sides with the adhesive points are in the field of view of the thermal imaging camera. The EyeVision HotGlue Inspector inspects if the glue has been applied to all adhesive joints and if the temperature of the glue at the joint is ranging inside the threshold to ensure the boxes keep the contents safe and do not fall apart during transportation from the production site to the shop or when transported by a customer.

Glue cannot be delivered if a nozzle is blocked or if the glue has not been fed. If there is no glue at an adhesive joint, this is detected automatically. It will be also detected, when the temperature of the glue is too low, which can happen when the heating is defective or due to a delay in the plant. In case only one or more adhesive joints are showing a temperature that is not high enough, then the error can be matched to the respective gluing device for repair. When all adhesive joints show a temperature which is too low then the carton can be ejected completely.

In addition to the digital interfaces, the EyeVision HotGlue Inspector has a standard tracker interface for a connection to a transport system, as well as a delayed ejection of goods. The tracker interface can be adjusted to the common standard tracker boards.

The set-up of the test facility for the HotGlue Inspector is a graphical process. The threshold for each adhesive joint can be either specified globally, for groups or for each adhesive joint separately. It is easy to detect the faulty adhesive joint and to repair the respective glueing device, says EyeVision, resulting in reduced plant downtime.

The EyeVision HotGlue system can be optimally adjusted, for example, when the adhesive joints should only be inspected on one side, then a system with only one camera is sufficient. When more than one side should be inspected, two or four cameras can be used.

In case large adhesive points should be inspected on the joints, then a cost-effective thermal imaging camera with 291 x 190 pixel resolution can be applied. If several small adhesive points should be inspected, a camera with 640 x 480 pixel resolution is necessary, to detect the hot glue points.

The graphically programmable EyeVision software offers an easy adjustment to the different inspections of adhesive joints. The system can be used with different inspection programs. Those can contain the temperature thresholds and the amount of adhesive points that should be detected.

An embedded mode allows the integration of the system into a complex plant for the results of the measurements and the evaluation images to be immediately available for the line control.

The EyeVision HotGlue system is available in different speed levels, depending on the applied cameras. The basic system can inspect 10 containers per second, whereas the high end system can inspect up to 60 containers per second.

In addition the HotGlue system can be equipped with standard 2D cameras. Those can then read codes (bar codes, DMC, QR or OCR/OCV) on the outside packaging, to guarantee a complete tracking of the production.