Wrappers for IP creates standardised ASICs

Wrappers for IP blocks have been used by Sondrel to create interchangeable standardised modules. The family of Architecting the future IP can be modified to precisely match customers’ ASIC requirements because it is based on a Scalable Architecture Framework (SAF). This architecture uses re-usable, modular IP blocks that each have a wrapper containing a standardised set of functions and interfaces. Each IP platform has been created by assembling the required blocks to meet the performance and functionality required for a particular application area.

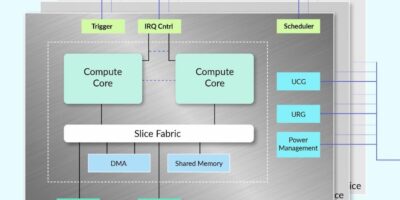

SAF is based on a chassis that encapsulates the foundation services and resources required in the class of application, i.e., transport fabric (NoC/NiC), system memory, power-clock-reset domains and system management (boot, configuration, FuSa and general application management functions). All the IP blocks connect and communicate with each other via the chassis to ensure easy integration and rearrangement.

The chassis is typically the part of the system that is unique, and Sondrel’s modelling processes allows the dimensioning and configuring of the chassis with regards to both the bus fabrics and the memory subsystem(s). The modelling also covers how the data processing requirements are partitioned across multiple heterogeneous processing slices for each mode of operation to meet power and performance constraints. The SAF then enables the integration to be performed in a reliable and predictable way, says Sondrel.

The blocks equate to the compute and I/O functions (CPUs, DSPs, PCIe) that are implemented in subsystems based on ‘slices’. Each slice has standard services and interfaces for interworking, synchronisation and communication. This enables the performance to be scaled, for example, three identical slices nominally triple the computing power. Additional functionality can be integrated by plugging the appropriate modular slice onto the chassis. Using slices also cuts overall project time as every slice in the library has been previously tested and verified, which also reduces project risk.

“It is like building blocks that have standardised studs that interconnect them, with a core Chassis that blocks connect onto,” explained Rowan Naylor, Sondrel’s principal system architect. Different sized blocks can be repositioned in the chassis to make way for new ones without having to restart the whole design, which would normally be the case, he said. The configurable interfaces of the encapsulate each IP block with supporting functions and services, such as clock reset and power management, so they require less work to connect or reposition them for customisation. “The standards will also mean that we can quickly create a wrapper for any IP supplied by the customer or from a third party,” added Naylor.

Graham Curren, Sondrel’s CEO, added, “There is nothing new about re-using IP but the practical implementation is invariably quite complicated as there is no universal standard for IP block interfaces so design time has to be spent on customising IP block interfaces for each implementation”. Sondrel created the SAF which uses modularisation with standard interfaces to practically re-use IP blocks and add and change as required. “In one instance, for example, we were able to shave six months off the design time of an ASIC with this new approach,” said Curren.

Sondrel used SAF to create the first five members of the Architecting the future family of IP platforms. The standardised modular approach means that an appropriate IP platform is selected and then customised by adding more computing blocks for improved performance or different functionality with the appropriate block from its library of blocks. Third party or customer IP, once wrapped, is added into the design in a similar way. Sondrel says SAF enables the company to dramatically reduce design time and design costs.

Graham Curren added: “This ‘blocks’ approach is particularly useful when the specification for the ASIC changes partway through the design process, as often happens when the customer refines requirements as the project progresses. Normally, such changes could require a complete redesign . . . . but now, with SAF, the modules are added onto or removed from the chassis”.